Comprehensive Guide on Flow Wrapping Machines from Different Competitors

Flow wrapping machines are essential in the packaging industry for products of various shapes and sizes. These machines pack items into pillow-style bags using a horizontal packaging process, ensuring efficiency and accuracy. Different competitors provide diverse models with unique features tailored for specific applications. This article explores various models of flow wrapping machines, focusing on their technical specifications, applications, features, and benefits.

1. Flow Wrapping Machine by Dolly Packaging Machine

Dolly Packaging’s Flow Wrapping Machine is designed for versatility, handling products such as food, vegetables, medical products, disposable items, stationery, and more. It offers customization options to meet specific needs and features a user-friendly control screen for easy adjustment of packaging speed, bag length, and language settings.

Technical Specifications:

| Feature | Details |

|---|---|

| Productivity | 30-180 pcs/min |

| Max Film Width | 450 mm |

| Bag Length | 150-450 mm |

| Bag Width | 50-180 mm |

Key Features:

- Advanced dual-frequency control for precise bag length management.

- Touch screen interface for easy setup and adjustment.

- Positioning stop function for accurate cutting and sealing.

- Customizable design options for various applications.

Applications: Dolly’s Flow Wrapping Machine is suitable for packing:

- Regular-shaped materials like towels, soap, bread, clothes, moon cakes, vegetables, and fruits.

- Disposable items such as medical gowns, masks, and hotel supplies.

- Stationery and other small objects like erasers and electrical accessories.

Process and Usage: The machine operates through a combination of feeding, film wrapping, sealing, and cutting mechanisms. The feeding system positions items on the conveyor, the film feeding device wraps the product, and the end sealing mechanism seals the package before discharging it. This setup makes the machine efficient for packing solid materials into pillow packages.

2. Automatic Film Splicing Flow Wrapper by TEFUDE

TEFUDE’s Automatic Film Splicing Flow Wrapper is a solution for companies aiming to maximize efficiency. The machine excels in handling snack foods, dairy products, and disposable items without the need to stop for film replacement, thanks to its high-precision splicing system.

Technical Specifications:

| Feature | Details |

|---|---|

| Automation Level | Full automatic film splicing |

| Servo Control | Independent control for cross and center seals |

| User Interface | Human-machine interface (HMI) |

Key Features:

- High-precision automatic film splicing system to maintain productivity.

- Independent servo motors for smooth sealing operations.

- Easy-to-use HMI for quick adjustments and settings.

Applications: This model is suitable for packaging:

- Food products like biscuits, chocolate bars, and snack foods.

- Disposable products used in various industries.

Process and Usage: The machine ensures a continuous operation by automatically splicing the film, thus eliminating downtime. The servo motors provide precise control over the packaging process, ensuring uniformity and quality.

3. Full Servo Flow Wrap Machine by Foshan Soontrue Machinery Equipment Co., Ltd

Foshan Soontrue’s Full Servo Flow Wrap Machine is designed for high-accuracy packaging of regular and solid products, such as biscuits, cakes, bread, and candy. This machine offers different models to suit various product sizes and packaging needs.

Technical Specifications:

| Model | Bag Length (mm) | Bag Width (mm) | Packing Speed (bags/min) | Max Film Width (mm) | Machine Weight (kg) |

|---|---|---|---|---|---|

| SL150 | 130-400 | 30-140 | 30-110 | 80-400 | 670 |

| SZ180 | 60-300 | 35-160 | 30-180 | 90-400 | 400 |

| SZ580 | 60-350 | 35-160 | 30-350 | 90-400 | 600 |

Key Features:

- Compact design with a smaller footprint.

- Optimized components for stable and high-speed operation.

- HMI system with memory function for easy operation and parameter setup.

- High accuracy in color mark tracking for precision sealing and cutting.

Applications: This model can handle a variety of products, including:

- Food items such as biscuits, cakes, and candies.

- Medical supplies like face masks and syringes.

- Hardware products and electronics.

Process and Usage: The machine integrates a servo control system to manage the mechanical motions precisely, ensuring that the packaging is consistent and efficient. The easy-to-use interface facilitates quick adjustments, and the machine’s compact structure saves space on production floors.

4. Horizontal Flow Wrap Packaging Machine by Coretamp Packaging Machine

Coretamp offers a range of horizontal flow wrapping machines suitable for packing various large-sized products into pillow or gusseted bags. Their models, such as the KT-350B/D and KT-400/450/600/700, are tailored for industries handling food, vegetables, and hardware.

Technical Specifications:

| Feature | KT-350B/D | KT-400/450/600/700 |

|---|---|---|

| Bag Length | Adjustable with dual frequency control | Adjustable |

| Packing Speed | 30-350 pcs/min | 25-350 pcs/min |

| Temperature Control | Independent PID control | Independent PID control |

Key Features:

- Dual frequency control for precise bag length and efficient film use.

- High sensitivity photoelectric eye for accurate sealing positions.

- Simple drive system for reliable operation and easy maintenance.

- Memory function in the interface for storing multiple packaging parameters.

Applications: This model is designed for diverse industries, including:

- Food industry for items like bread, biscuits, and sausages.

- Vegetable and fruit packaging.

- Medical products such as gloves, syringes, and masks.

- Daily use items like plastic cups, cutlery, and wipes.

Process and Usage: The machine uses a rotary flow system, wrapping products efficiently and with precision. It incorporates a self-diagnosis feature, displaying errors on the screen for quick troubleshooting. The PID control system adapts to various packaging materials, ensuring versatility.

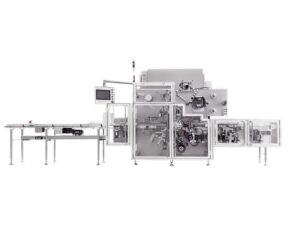

5. BZM500 Automatic Overwrapping Machine by San-Ke

The BZM500 from San-Ke is an automatic overwrapping machine designed for high-speed packaging of products sensitive to humidity, such as chewing gum and hard candies. It offers automation in product aligning, film feeding, cutting, wrapping, and folding.

Technical Specifications:

| Feature | Details |

|---|---|

| Output | Max. 200 boxes/min |

| Box Size Range | Length: 45-160 mm; Width: 28-85 mm; Height: 10-25 mm |

| Connected Load | 30 kW |

| Machine Dimensions | Length: 5940 mm; Width: 1800 mm; Height: 2240 mm |

Key Features:

- Automatic product alignment for efficient wrapping.

- High-speed film feeding and cutting system.

- Humidity protection to extend product shelf life.

Applications: The BZM500 is ideal for products requiring precise wrapping, such as:

- Chewing gum, hard candies, and chocolates.

- Other humidity-sensitive packaged goods.

Process and Usage: The machine combines flexibility and automation for rapid packaging. It aligns products automatically, feeds and cuts the film, wraps, and folds it in a finseal style. The automatic process improves production rates while maintaining product integrity.

Conclusion

Flow wrapping machines from various competitors provide a range of technical features and customization options, making them suitable for a broad spectrum of products. From Dolly Packaging’s versatile model to TEFUDE’s advanced film splicing system, and Foshan Soontrue’s high-speed options, these machines cater to specific needs within the packaging industry. Each machine offers unique benefits in terms of efficiency, flexibility, and ease of use, ensuring that businesses can choose the best fit for their production requirements. We recommend customers who need help locating the right suppliers. Check us out for more products we recommend.

Comparison Summary:

| Brand | Model | Applications | Speed (pcs/min) | Max Film Width | Key Feature |

|---|---|---|---|---|---|

| Dolly Packaging | Flow Wrapping Machine | Food, medical, daily items | 30-180 | 450 mm | Dual frequency control, customization |

| TEFUDE | Automatic Film Splicing | Snacks, disposables | High-speed | – | Film splicing without downtime |

| Foshan Soontrue | Full Servo Flow Wrap | Food, medical, hardware | 30-350 | Up to 600 mm | High accuracy, compact design |

| Coretamp | KT-350B/D & KT-450/600/700 | Large-sized products | 25-350 | – | PID temperature control, easy HMI |

| San-Ke | BZM500 Overwrapping | Chewing gum, candies | 200 boxes/min | 180 mm | Humidity protection, high-speed |

Selecting the right machine depends on product type, packaging speed requirements, and operational flexibility. With continuous technological improvements, flow wrapping machines are evolving to meet the dynamic needs of the packaging industry.