Cartoning Machines: Features, Functions, and Competitor Comparisons

Cartoning machines are essential in the packaging industry, automating the process of erecting, filling, and sealing cartons for various products, including pharmaceuticals, food items, cosmetics, and consumer goods. These machines enhance production efficiency, reduce labor costs, and ensure consistent packaging quality. This article explores different cartoning machines from various competitors, focusing on their technical features, quality, functions, and applications.

1. Functions of Cartoning Machines

Cartoning machines automate the packaging process and offer various functions depending on the product and packaging requirements:

-

- Box Erecting: The machine forms cartons from flat blanks using suction cups, mechanical arms, or robotic manipulators.

- Product Loading: Depending on the product type, machines may use conveyor systems, robotic arms, or manual loading to fill cartons.

- Leaflet Insertion: In industries like pharmaceuticals, machines can insert leaflets or instructions into the cartons automatically.

- Carton Sealing: Sealing mechanisms may include hot glue, tuck-in flaps, or adhesive tape for secure packaging.

- Coding and Marking: The machines can be equipped with printers to mark batch numbers, expiry dates, or other relevant information on cartons.

- Quality Control: Automated rejection systems remove defective cartons, ensuring product quality.

2. Competitor Analysis: Technical Features and Quality

| Company | Model | Speed | Carton Size Range | Material | Optional Features | Automation Level |

|---|---|---|---|---|---|---|

| Dolly Pack | DL-ZH-50 Vertical Cartoning | 20-50 pcs/min | 60x20x20 mm to 200x80x80 mm | 250-350 g/m³ cardboard | Leaflet insertion, hot glue, date coding | Semi-automatic |

| Soontrue | SJZX-21001A | Customizable | Various (customizable) | Corrugated, board paper | 3-axis manipulator, air suction, robotic control | Fully automated |

| Poly Tech | Automatic Cartoning Machine | High-volume | Customizable | Cardboard | Integration with existing lines, flexible carton size | Fully automated |

| Antai Packing | Automatic Encasing Machine | 30-120 boxes/min | 65-150×30-85×12-45 mm | 250-350 g/m² cardboard | Product testing, automated leaflet folding | Fully automated |

| UBL Packing | UBL Nucleic Acid Cartoning | 40-60 boxes/min | 80-200×50-100×15-30 mm | 250-400 g white cardboard | Weighing, coding, integrated sealing and labeling | Fully automated |

3. Detailed Review of Cartoning Machines

Dolly Pack: DL-ZH-50 Vertical Cartoning Machine

Model: DL-ZH-50

Productivity: 20-50 pcs/min

Application: Pharmaceuticals, food, cosmetics

Quality: High durability, consistent output

The DL-ZH-50 from Dolly Pack is a vertical cartoning machine ideal for small outputs and multi-size carton packaging. It is designed to save labor costs while providing high production efficiency. The system allows for various automation levels, depending on the user’s needs. It includes optional features like leaflet insertion, hot glue, and coding.

- Strengths:

- Versatile for different industries

- Simple design, low maintenance

- Automatic detection and rejection systems for quality control

- Applications:

- Food packaging (e.g., candy)

- Pharmaceutical packaging (e.g., bottles, tubes)

- Cosmetics packaging

Soontrue: SJZX-21001A

Speed: Customizable

Automation: Fully automated with a 3-axis manipulator

Integration: Easily connects with other packaging systems

Soontrue offers advanced automation with its Box Case Packing Machine. The machine uses a 3-axis manipulator, allowing precise and flexible movement in 3D space for efficient product pick-up and placement. It integrates seamlessly with other packaging machines, making it ideal for high-speed production environments.

- Strengths:

- Robust R&D support and technical customization

- High-speed processing with stable, accurate placement

- Low energy consumption and built-in safety mechanisms

- Applications:

- Food industry packaging (e.g., bakery products, snacks)

- Chemical and daily necessity packaging

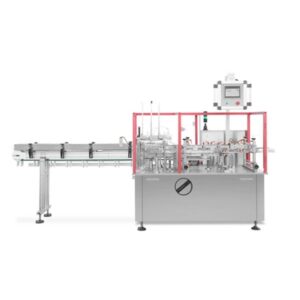

Poly Tech: Automatic Cartoning Machine

Flexibility: Customizable to specific packaging requirements

Automation: Fully automated with integration options

Poly Tech’s Automatic Cartoning Machine is known for its flexibility and integration capabilities. It offers high-speed packaging for various products, providing options for carton size and shape adjustments, which suits industries with diverse product types.

- Strengths:

- Versatility in carton customization

- Full automation reduces labor requirements and errors

- Durable construction for long-term use

- Applications:

- High-volume consumer goods packaging

- Electronics and gadget packaging

Antai Packing: Automatic Encasing Machine

Speed: 30-120 boxes/min

Features: Multi-function with automated leaflet folding

The Automatic Encasing Machine by Antai Packing offers versatile packaging for products like blisters, sachets, and bottles. It integrates with other systems like blister packing machines and labeling machines to form a comprehensive packaging line.

- Strengths:

- High compatibility with various product specifications

- Comprehensive automation, including quality checks and rejections

- Precision in leaflet folding and insertion

- Applications:

- Pharmaceutical packaging (e.g., blister packs)

- Cosmetic and personal care product packaging

UBL Packing: Nucleic Acid Detection Cartoning Machine

Model: UBL Test Kit Cartoning Machine (HL-Z-C120)

Speed: 40-60 boxes/min

Specialization: Designed for nucleic acid detection test kits

UBL’s specialized cartoning machine targets the medical sector, specifically for test kit packaging. It automates the process of opening, filling, and sealing boxes while maintaining precision and speed. Its design features ensure efficient handling of small accessories and components needed in medical packaging.

- Strengths:

- Tailored solutions for medical and diagnostic packaging

- Integrated quality checks and automated coding systems

- Use of premium components for reliability (Siemens PLC, stainless steel)

- Applications:

- Medical test kits

- Diagnostic equipment packaging

4. Comparison Table of Features and Applications

| Feature | Dolly Pack | Soontrue | Poly Tech | Antai Packing | UBL Packing |

|---|---|---|---|---|---|

| Leaflet Insertion | Yes (optional) | Yes | No | Yes | Yes |

| Product Range | Small-to-medium items | Customizable | Wide range | Blister, sachets, bottles | Test kits, medical supplies |

| Quality Control System | Automatic reject system | Yes | Yes | Yes | Automated weighing system |

| Automation Level | Semi-automatic to full | Fully automated | Fully automated | Fully automated | Fully automated |

| Industry Applications | Pharmaceuticals, cosmetics | Food, daily necessities | Consumer goods | Pharmaceuticals, cosmetics | Medical and diagnostic kits |

5. Choosing the Right Cartoning Machine

When selecting a cartoning machine, manufacturers need to consider several factors:

-

- Speed Requirements: Machines like those from Soontrue and Antai Packing offer high-speed packaging options suitable for high-volume production lines.

- Product Type and Size: For specialized products such as test kits (UBL) or multi-size cartons (Dolly Pack), selecting a machine tailored to specific packaging needs ensures efficiency and cost-effectiveness.

- Integration Capability: If the goal is to automate the entire production line, Poly Tech and Soontrue machines are excellent choices due to their ease of integration with other packaging systems.

- Automation Level: Companies with varying product types may benefit from machines offering semi-automatic options, such as Dolly Pack’s DL-ZH-50, while large-scale operations may opt for fully automated systems like Antai’s or Soontrue’s.

Conclusion

Cartoning machines are vital for automating packaging processes across diverse industries. By understanding the technical features, applications, and strengths of different models from leading companies such as Dolly Pack, Soontrue, Poly Tech, Antai Packing, and UBL, manufacturers can make informed decisions to enhance their packaging efficiency and product quality. We help in recommending, don’t hesitate to contact us for help!