Bottle Labeling Machine: Overview, Functions, and Competitor Comparisons

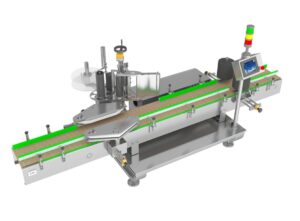

A bottle labeling machine is an essential piece of equipment in industries such as food and beverage, pharmaceuticals, cosmetics, and chemicals. Its primary function is to apply labels efficiently and accurately to bottles of various shapes and sizes, providing an organized, visually appealing, and informative presentation of the product. With automation becoming increasingly critical for improving production speed and accuracy, labeling machines play a vital role in streamlining operations and reducing manual labor.

This article dives into the details of bottle labeling machines, discussing their technical features, quality, usage, and applications across different industries. It also compares different machines from leading competitors, highlighting their key functions and unique advantages.

Key Functions of Bottle Labeling Machines

Bottle labeling machines automate the process of applying labels to bottles, ensuring consistency, precision, and speed. Common functions include:

-

- Wrap-around Labeling: The machine applies labels to cylindrical bottles by wrapping the label around the entire surface.

- Front and Back Labeling: Labels are applied to both the front and back of the bottle, which is common for food, beverage, and personal care products.

- Single-side Labeling: Ideal for flat or square-shaped bottles, the machine applies the label on just one side.

- High-speed Labeling: Some machines can label hundreds of bottles per minute, which is crucial for large-scale production facilities.

- Integration with Production Lines: These machines are often integrated into larger production lines, working in tandem with filling and capping machines.

Technical Features Comparison

The following table compares technical features of different bottle labeling machines from leading competitors.

| Feature | DL-LB-RB (Round Bottle) | TN-200LDS (Square/Flat Bottles) | ST-45B (Single Side) | SBM-LM8021CG (Cold Glue) |

|---|---|---|---|---|

| Labeling Speed | Up to 80 bottles/min | 5L: 2500 BPH, 25L: 1500 BPH | 80-200 bottles/min | Variable, up to 150 bottles/min |

| Labeling Accuracy | ±0.5-1mm | ±1mm | ±1mm | High precision |

| Bottle Diameter | 30-100 mm | 30-95 mm | ≥30 mm | Round bottles of all sizes |

| Label Size | 10-300 mm (L), 10-140 mm (H) | ≤300 mm (L), ≤200 mm (H) | 190 mm max width | Customizable for each bottle |

| Power | 220V, 50-60 Hz, 0.3 kW | Programmable with servo motor | 380/220V, 50 Hz, 2300W | Adjustable speed control |

| Dimensions | 1600×1400×860 mm | Customizable dimensions | 2400×1200×1500 mm | Customizable dimensions |

| Weight | 250 kg | 400 kg | 280 kg | Adjustable settings |

Quality and Build of Bottle Labeling Machines

-

-

- DL-LB-RB Round Bottle Labeling Machine: Known for its stable performance, this machine features a Siemens PLC control system and Panasonic servo motor, ensuring precise label application. The machine is built according to European CE standards, emphasizing durability and reliability.

- TN-200LDS (Square/Flat Bottles): This model adopts a programmable interface with servo-driven labeling. Its robust design ensures smooth operation and label precision. The machine is particularly effective for labeling square and flat bottles, with excellent adjustment capabilities for different product sizes.

- ST-45B Single Side Labeling Machine: This machine excels at high-speed labeling for cosmetic and personal care industries. With its servo motor providing closed-loop control, it avoids common problems seen in stepper motors, such as inaccurate label placement. Its sponge roller technology ensures a smooth, bubble-free application.

- SBM-LM8021CG Cold Glue Labeling Machine: Built for round bottles, this cold glue labeler uses high-precision components, including a specialized rubber roller and vacuum suction label system. It offers a robust solution for high-speed production environments like food and chemical plants.

- DL-LB-RB Round Bottle Labeling Machine: Known for its stable performance, this machine features a Siemens PLC control system and Panasonic servo motor, ensuring precise label application. The machine is built according to European CE standards, emphasizing durability and reliability.

-

Comparison of Machine Functions

| Function | DL-LB-RB (Round Bottle) | TN-200LDS (Square/Flat Bottles) | ST-45B (Single Side) | SBM-LM8021CG (Cold Glue) |

|---|---|---|---|---|

| Wrap-around Labeling | Yes | No | No | Yes |

| Front and Back Labeling | Yes | Yes | Yes | No |

| Single-side Labeling | No | Yes | Yes | No |

| High-speed Labeling | Up to 80 bottles/min | 2500 BPH (5L), 1500 BPH (25L) | 200 bottles/min | Yes, adjustable |

| Integration with Production Line | Yes | Yes | Yes | Yes |

| Cold Glue Application | No | No | No | Yes |

Usage and Applications

Bottle labeling machines are used across various industries, such as:

-

-

- Pharmaceutical Industry: Labeling medicines, syrups, and health products for regulatory compliance.

- Food and Beverage Industry: Applying labels to water bottles, juices, sauces, and other consumables.

- Cosmetics and Personal Care: Labeling shampoos, lotions, oils, and other cosmetic products.

- Chemical Industry: Labeling chemicals like detergents, lubricants, and cleaning products.

- Wine and Spirits: For premium liquor bottles that require aesthetic and regulatory labeling.

-

The DL-LB-RB Round Bottle Labeling Machine is ideal for labeling round containers in industries like pharmaceuticals, cosmetics, and food and beverage. Its wrap-around labeling ensures full label coverage, making it suitable for products that require branding or detailed product information.

The TN-200LDS is perfect for labeling flat and square bottles, commonly found in personal care and household chemical products. This machine’s programmable interface and high precision make it versatile and adaptable for different container sizes.

The ST-45B Single Side Labeling Machine is widely used in cosmetics, especially for products that come in irregular-shaped bottles. Its high-speed labeling capacity is particularly beneficial for large-scale cosmetic production lines.

Finally, the SBM-LM8021CG Cold Glue Labeling Machine is designed for round bottles using cold glue labeling. This machine is well-suited for the food and chemical industries, where efficient, high-volume labeling is required.

Working Process of Bottle Labeling Machines

-

-

- Bottle Loading: Bottles are manually placed on a conveyor or automatically fed into the system via a bottle turntable.

- Bottle Separation: A bottle separator ensures consistent spacing between bottles, ensuring smooth and stable operation.

- Automatic Label Application: The machine senses the presence of each bottle, applies the label, and fastens it to the surface using either wrap-around or side labeling techniques.

- Label Securing: A label paste device or sponge roller ensures that the label is securely attached, with no air bubbles or wrinkles.

- Bottle Ejection: Once labeled, the bottles are either conveyed to the next stage of production or collected for packaging.

-

Advantages of Bottle Labeling Machines

-

-

- Automation: Automating the labeling process significantly reduces labor costs, speeds up production, and improves precision.

- Customizability: Machines can be adjusted for different bottle sizes and label types, providing versatility in production lines.

- Integration with Other Equipment: Labeling machines can work alongside other machinery, such as filling and capping machines, creating a fully automated production line.

- High Precision: These machines ensure that labels are applied accurately, avoiding misaligned or wrinkled labels that can impact brand perception.

- User-friendly Interfaces: Many models, such as the DL-LB-RB and TN-200LDS, come equipped with touch screens and programmable settings, making them easy to operate.

-

Conclusion

Bottle labeling machines are indispensable in today’s automated production environments, offering high-speed, precision labeling for various industries. From pharmaceutical to cosmetic and food sectors, the flexibility and efficiency of these machines help manufacturers meet the demands of modern production.

Competitors like the DL-LB-RB, TN-200LDS, ST-45B, and SBM-LM8021CG offer various specialized functions, making them suitable for a wide range of applications. Choosing the right machine depends on the type of bottles, production scale, and labeling requirements specific to the manufacturer’s industry.

For referrals and recommendations, Contact Us.